IonCore was established in 2012 with the aim of producing the most advanced and usable 3D printer aimed at the consumer market.

Richard Dinan, star of E4’s Made in Chelsea, entrepreneur and co-founder of the Phantom prepaid dining Card, and his business partner, finance and media expert and fellow co-founder of the Phantom Card, Alexander Nall-Cain, teamed up with CNC and robotics specialist James Marchant, to launch the Zinter® PRO 3D printer at the beginning of January this year.

Richard has been focusing much of his attention on the manufacturing and engineering sectors over the last few years, and is well known for being constantly on the look-out for new and cutting edge technologies, while Alexander’s aptitude for finance and investment, not only in his media and night club businesses, means he has also enjoyed success last year with new and groundbreaking ventures.

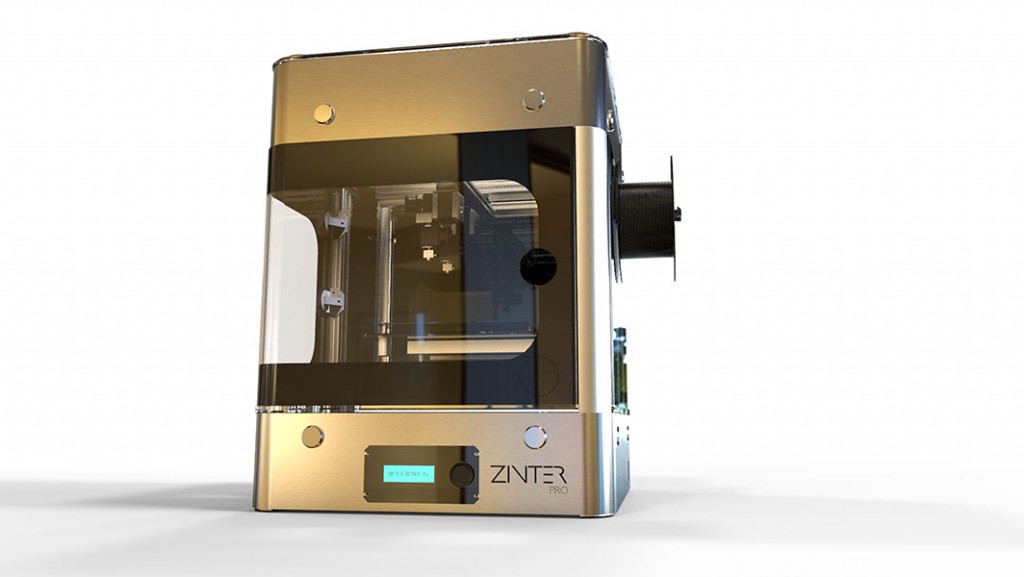

Linking together with IonCore CEO James, who has been a leader in design, engineering, manufacturing and 3D technology since 2003, the three businessmen set about creating a product capable of bringing 3D printing to the masses. The Zinter® PRO has had considerable hype thanks in part at least to Richard’s celebrity status, but also to its careful design that clearly marks it out as a stylish, ‘must-have’ gadget as well as a functional piece of technology.

Everyone here at CADagency was very excited to hear more and we managed to get hold of the CEO and Directors and asked them some questions.

With the amount of 3D printers on the market in the ‘affordable’ price bracket now in the dozens, what made you want to join that market, and why does yours stand out?

Ion Core was founded by James Marchant who along with his design and research teams has a huge track record of designing bespoke robotic, electrical and CNC control systems. As the patents expired allowing companies to produce low cost 3D printers, James identified his team’s ability and experience to create a product that was perfect in an engineering sense and better than all competitors. James also identified the requirement for a consumer level 3D printer that not only performed the best using the best mechanical, electrical and linear components but it needed to look the best too. Having looked at the more established 3D printers on the market, despite the parent company’s marketing power behind them it is clear to an engineering trained eye some uses of components and configurations are not mechanically sound. In a nutshell the simple answer to your question is that we knew we could make a better 3D printer at this level than anyone else.

How long did the Zinter® PRO take from concept to launch?

It’s quite hard to put a figure on as our 10 years track record in similar industries are not directly towards the Zinter® PRO development but are the foundations IonCore stands on. We have had a team working on Zinter® PRO directly for 18 months. We wanted to ensure our first product launched to the public was as good as it could possibly be in every way.

Where any already available 3D printers involved in the process of creating the Zinter® PRO?

We looked very closely at reviews of other printer’s, discussions with owners of other 3D printers as well as our own hands on experience to fully understand the elements are weak in the current range of low cost desktop 3D printers. We used this in depth analysis during the development of Zinter® PRO and ensured we produced a product superior to others. One of our designers privately owned a more well-known 3D printer model that he used in his other design work. It has subsequently been returned to the manufacturer as he took on one of our early Zinter® PRO prototypes. A range of weak products currently on the market at the consumer desktop level was a real driving force behind everyone involved with the Zinter® PRO development and our passion to create products in this sector where for too long there has been a real lack of competition.

What was the biggest challenge in creating the Zinter® PRO?

Funnily enough unlike most 3D printer startups popping up every day at the moment, with our experience and expertise the machine itself in terms of mechanical movement and electronics, calibration and software was rather straightforward. To scale up eventually you have to start using some outside manufacturers, especially on the initial low volume production runs, and not being in control of their factories/time/quality control is often not fun and was a challenge. As Zinter® PRO production has now greatly stepped up we now control as much manufacturing in house as possible.

The Zinter® PRO is beautiful to look at, how important was the aesthetic design, and are you hoping to create an iconic ‘iPrinter’ style and status with it?

In order to take a 3D printer from the early adopters, the tinkerers, to a more mass market consumer level product that aesthetic design was a very important factor. We were careful that, with the added features of Zinter® PRO such as the fully enclosed environment, we integrated these perfectly into the look and feel of the unit, and really concentrated on producing a great looking a machine to compliment the advanced features and superior components and build quality Ion Core products will become known for.

The biggest reported problem with 3D printing currently seems to be ease of use, what are you doing to ensure the Zinter® PRO can be used by everyone, not just design experts?

Yes you are correct and again this was a big driving factor behind Zinter’s conception and development. We were frustrated with companies letting customers of this innovative and ground breaking technology down by launching inferior products that did not live up to their hype. Maybe this wasn’t such an issue early on as consumer 3D printers were self-assemble kits and the enjoyment was making the kit as much as using the final product for 3D printing with. With Zinter® PRO we totally moved away from a kit and produced a simple out the box product like you’d expect from a conventional office paper printer. We have spent well over a year testing and calibrating different components from mechanical movement to the extruder technology giving us the confidence to say this is the best consumer level 3D printer on the market. As well as ensuring Zinter® PRO is easy to use and reliable we have made the machine full of features required by those people that really care about that 3D prints.

Zinter® PRO has a fully heated build platform, two extruders, and the easiest and most full featured software for turning CAD models into code used by the machine. We packaged this up as a beautiful product and let it loose over 6 months ago to a large range of private testers from around the world. We have ensured Zinter® PRO was easy to use for the average consumer yet had all the features required of a designer or professional user.

Do you provide your own software with IonCore products if not, which software is compatible?

We have teamed up with the makers of Simplfy3D™ software based in the US. This software will turn your 3D CAD design into code that is used by Zinter® PRO. We were very impressed with the software they had created a couple of years ago and have been working with them since to ensure the software and Zinter® PRO work perfectly together and include all the pre-configured settings allowing ease of use by an average consumer yet access to a huge range of advanced features for the professional user. One feature we particular love is the ability to not only automatically add support material for those models that require it, but also giving the user manual control to add and remove additional support material as they wish. The ability to nest multiple designs on the heated build platform and print multiple items during a single print is also a real improvement in efficiency.

How important do you see 3D printers becoming over the next few years?

Very, we can see the uptake of 3D printers has been huge over the last few years and believe this will only increase as the technology improves both in plastic 3D printing and with the new range of materials we know we will see over the next 12 months.

Even though the Zinter® PRO been on the market for a month, how has public response been so far?

Publicly Zinter® PRO has only been available for a month or so however privately Zinter® PRO has been around for a lot longer. During our testing and calibration phase we produced a number of Zinter® PRO units and shipped them around the world to a range of average consumers as well as industry experts so we knew before our public launch a month ago the feedback would be great with regards to the printing capability of the Zinter® PRO. Whilst this testing phase was on going we took our design team and focussed them on the look and feel of the Zinter® PRO. Is was in fact these initial testers that pushed us to release Zinter® PRO for sale early on and start accepting pre-orders whilst we scaled up mass production in January 2014. They kept telling us how we had to release Zinter® PRO to the world now and let people know about it. We published the product renders just before Christmas and the response has been truly amazing. We have had nothing but positive comments from people appreciating the look of Zinter PRO, and the response from reseller applicants and industry experts has also been amazing. Never before have I encountered such a huge number of applications for reseller status in any industry or for any product as we have received for Zinter® PRO.

What does the future hold? Will there be a Zinter PRO2 or Zinter Mini?

We’ve spent a long time developing Zinter® PRO so for now our time and focus is launching this product and developing Ion Core’s distribution throughout the world. We have a range of initiatives that will soon be announced to help with Zinter PRO’s launch and adoption across the globe. The ZintShare platform is coming early 2014 allowing our customers to exchange 3D printing files easily. Looking further to the future like any technology company we continuously invest a lot in R&D and have a number of products in the additive manufacturing sector to come later in 2014 onwards both from IonCore and some of our partner companies.

The Zinter® PRO 3D Printer £2,350 is available now from the IonCore website with a lead time of 6 weeks.